Fan Applications

Fan Applications

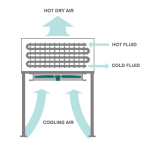

One of the most common applications for axial fans is cooling by transfer heat to ambient air. The process stream to be cooled can either be a liquid or a gas.

The heat exchanger equipment utilized for this heat transfer is divided into three primary categories

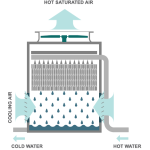

- The fluid, such as water, is in direct contact with the air and is cooled by sensible and latent heat exchange. This type of equipment includes factory assembled cooling towers and field erected cooling towers.

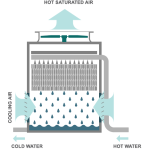

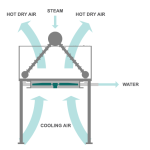

- The liquid or gas within the tubes is cooled or condensed by water flowing over the tubes. The water comes then in direct contact with the air. This type of equipment incudes closed circuit cooling towers and evaporative condensers.

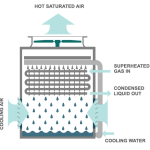

- The process liquid or gas inside tubes is cooled or condensed by air that passes over the tubes. This type includes air cooled condensers and air cooled heat exchangers.

Each of the different product types has different operating and performance characteristics. Consequently, there have varying fan requirements,

Factory assembled cooling towers are assembled in a factory and transported by truck to the installation location. They can be used for both HVAC and industrial applications. The fans for this application typically range in size from 4 to 13 feet in diameter. The key criteria for these applications are corrosion resistance and noise control.

Field erected cooling towers are large custom designed cooling towers for specific locations and applications. The components are manufactured and shipped to the project location. The cooling tower is then field assembled at the project location. They are used for power plants and larger industrial plants. The fans for this application can exceed 40 feet in diameter and have very large drive systems, e.g. 200 – 400 HP ( 150 – 300 KW ). The large quantity of components within the cooling tower structure can interact with the fan in a variety of ways, sometimes unexpectedly. It is essential that the fan design has high structural integrity and a low resonance potential or vibration stability. Corrosion resistant fan materials are required for corrosive applications such as sea water cooling.

Evaporative condensers and closed circuit cooling towers are utilized in both HVAC and industrial applications. They are primarily factory assembled products that are transported by truck to the installation location. The fans for this application have the same requirements as those for package cooling towers.

Air cooled heat exchangers are devices for cooling or condensing a process fluid within finned tubes. Depending on the size of the exchanger, they can be transported fully assembled or in components for field assembly. These fans range in size typically from 4 to 22 feet. In the larger units, structural components can interact with the fan causing undesirable vibrations. It is essential that the fan design has high structural integrity and a low resonance potential or vibration stability.

Air cooled condensers are often substituted for the field erected cooling towers for applications in power stations where fresh water is limited or nonexistent. These installations can be very large and consist of 50 to over 300 fans. The fans used in these applications here have similar requirements as those for field erected cooling towers except there is generally a reduced need for corrosion resistance materials. However, due to the size and method of support, vibration control is paramount. Catastrophic failures can result in very expensive corrective action programs. Also due to the large quantity of fans deployed, fan efficiency and energy consumption are very important concerns.

Industrial ventilation is an important application for axial fans. In general, these fans are ranging in diameter from 3 to 8 feet. Most applications require very high static pressures, therefore fans are requested to run at very high tip speeds.